American Plastics LLC HDPE Pipe Supplier: Ensuring Your Projects Stay on Time and Budget

Enhance Your construction Projects With Trustworthy Pipeline Supplies Basics

In the construction industry, the selection of pipeline materials plays an essential duty in task success. Quality materials can greatly affect resilience and security. Various pipe types serve distinct purposes, from water drainage to water. Recognizing these essentials is important for efficiency. Nevertheless, several forget the subtleties of picking the right components and suppliers. Discovering these variables can lead to better outcomes for any construction endeavor. What should be considered next?

Recognizing the Significance of Top Quality Pipeline Products

While lots of may ignore the relevance of high quality pipe supplies, their duty in different construction and pipes tasks can not be overstated. The integrity of a project typically rests on the reliability of products made use of, especially pipes. Top notch pipelines assure durability, decreasing the possibility of leakages and failures that can lead to pricey repair work. They contribute to the total security of pipes systems, avoiding hazardous circumstances that could emerge from inferior products.

Purchasing quality pipe supplies additionally enhances the efficiency of installments. Well-manufactured pipelines fit with each other flawlessly, reducing labor time and possible problems throughout assembly. Furthermore, they frequently come with warranties that offer peace of mind for homeowners and service providers alike. In a market where security and efficiency are extremely important, choosing the best pipe supplies is not simply a preference; it is a need that influences the longevity and success of construction endeavors.

Kinds Of Pipe Materials and Their Applications

The choice of pipeline products is vital for making certain the effectiveness and longevity of different applications. Various products, such as PVC, steel, and copper, each deal distinct properties that match details needs. Comprehending these materials and their suitable usages can considerably impact the efficiency of plumbing and commercial systems.

Typical Pipeline Product Kind

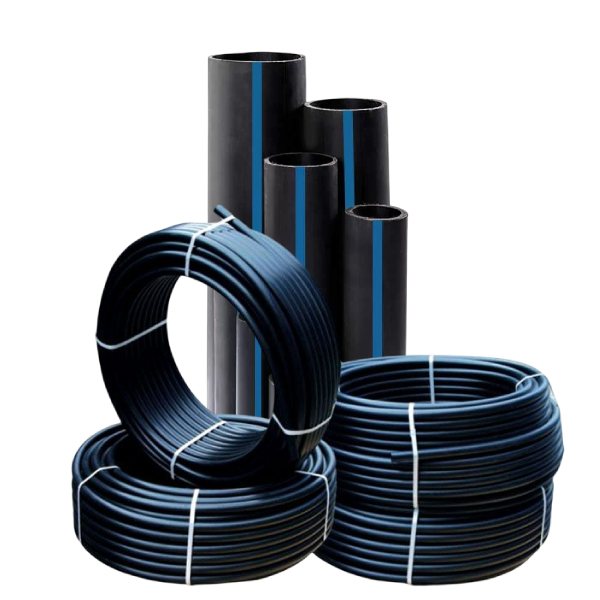

Pipeline products play a crucial function in different construction and plumbing applications, each kind offering distinct properties suited for specific functions. Usual pipe materials include PVC, which is lightweight and resistant to deterioration, making it optimal for drainage and watering systems. Copper pipelines are renowned for their sturdiness and thermal conductivity, often utilized in water lines. American Plastics LLC. Steel pipes, stainless or especially galvanized, are preferred for their toughness and long life, ideal for high-pressure applications. PEX, or cross-linked polyethylene, provides flexibility and ease of installation, primarily utilized in domestic plumbing. Each material type addresses particular requirements, making sure that construction and pipes projects attain superior performance and longevity while sticking to sector requirements

Application-Specific Pipe Uses

Understanding the specific applications of various pipeline products improves decision-making in construction and plumbing tasks. Various materials serve distinctive objectives based on their properties. PVC pipelines are commonly made use of in water drainage systems due to their corrosion-resistant and lightweight nature. Copper pipes are preferred for water supply lines, as they are durable and have antimicrobial properties. In commercial settings, steel pipelines are favored for their toughness and capability to handle high-pressure applications. In addition, PEX pipes supply versatility and ease of setup for domestic pipes. Each sort of pipe product is tailored for certain needs, making it essential for experts to pick the right option to ensure efficiency, security, and long life in their tasks.

Necessary Pipeline Fittings for Efficient Installments

Elbows permit directional modifications, while tees branch off into extra lines, improving system adaptability. Combinings ensure protected connections between pipeline areas, stopping leakages and preserving architectural stability. Reducers play an essential function in moving in between different pipeline diameters, sustaining reliable flow and decreasing stress loss.

The selection of high quality pipeline installations is essential, as subpar products can lead to corrosion, leaks, and system failings. Therefore, investing in reliable installations not just boosts setup efficiency however likewise adds to the long life and efficiency of the entire piping system.

The Function of Valves in construction Jobs

Valves serve a vital function in construction jobs, serving as control systems that control the flow of fluids within piping systems. They are crucial for ensuring security and performance in various applications, from water supply to chemical processing. Various kinds of shutoffs, such as gateway, world, and round shutoffs, offer special benefits, enabling precise control over circulation rates and pressure degrees.

Along with flow policy, shutoffs play a crucial role in stopping backflow and securing like it systems from overpressure scenarios. Their installation can considerably impact the total capability of a task, affecting upkeep demands and functional prices.

Additionally, the selection of ideal shutoff materials is important, as they have to stand up to certain environmental problems and liquid characteristics. Proper valve integration within construction designs not just boosts system integrity yet additionally adds to attaining conformity with market requirements and guidelines, eventually resulting in successful job completion.

Exactly how to Pick the Right Pipeline Supply Supplier

Picking the appropriate pipeline supply supplier requires mindful factor to consider of a number of vital factors. It is important to assess the dependability of the vendor, evaluate the top quality requirements of their products, and compare their rates and solutions. These steps will certainly help assure that the chosen supplier satisfies project demands efficiently.

Analyze Vendor Reliability Variables

When examining potential pipeline supply vendors, it is essential to consider various aspects that contribute to their integrity. To start with, the vendor's experience in the sector can supply understanding into their capacity to meet task needs. American Plastics LLC HDPE Pipe Supplier. Furthermore, determining their monetary security is important, as it indicates their capacity to meet long-term contracts. Timeliness in distribution and responsiveness to inquiries are likewise substantial indicators of a supplier's dependability. Examining customer testimonials and testimonies can supply valuable perspectives on their service history. Lastly, comprehending their supply chain monitoring techniques can disclose their capacity to take care of unexpected interruptions. By thoroughly taking into consideration these variables, construction experts can make enlightened choices when selecting pipe supply suppliers for their projects

Assess Product Quality Requirements

Reviewing item top quality criteria is essential for choosing the best pipeline supply vendor, as the sturdiness and performance of pipes directly impact task success. It is crucial to evaluate the materials made use of in producing pipes, as top quality products ensure longevity and resistance to ecological aspects. Vendors need to provide qualifications and conformity with market standards, which can suggest dependability and safety. Furthermore, reviewing item requirements, such as pressure ratings and deterioration resistance, uses understanding into the suitability of pipes for details applications. Conducting thorough research study on a supplier's reputation, including consumer reviews and testimonies, can further assist determine the high quality of their items. Ultimately, prioritizing top quality standards will add to overall job performance and effectiveness.

Compare Prices and Providers

Exactly how can one efficiently contrast rates and solutions among pipe supply vendors? To make a notified choice, it is necessary to gather thorough quotes from multiple providers, making certain that comparable items and amounts are being contrasted. Evaluating the overall expense, consisting of delivery and any additional fees, is important (American Plastics LLC). Additionally, analyzing the variety of solutions used-- such as shipment choices, client support, and return policies-- can impact overall fulfillment. It is likewise useful to read consumer testimonials and endorsements to determine integrity and solution quality. Finally, think about the vendor's credibility within the industry, as a reputable vendor may my company give far better support and uniformity. By taking these steps, one can pick a pipe supply vendor that straightens with both budget plan and project demands

Expense Financial Savings With Trustworthy Pipe Products

Reputable pipe materials function as a keystone for expense financial savings in both property and commercial tasks. By choosing high-quality products, specialists can reduce the threat of leaks and failings, which commonly cause pricey repair services and project delays. Buying dependable pipelines ultimately minimizes upkeep expenses in time, as these items commonly offer higher longevity and longevity.

Furthermore, trustworthy distributors frequently supply affordable rates, permitting builders to stay within budget plan without compromising top quality. Bulk buying choices and discount rates for long-lasting collaborations better boost economic performance.

In addition, making use of reliable pipeline products can simplify installment procedures, as these products are developed for compatibility and ease of use. This efficiency not just conserves labor prices yet likewise shortens project timelines. In general, adopting dependable pipe products is a critical technique that promotes substantial price financial savings while making sure project stability and client contentment.

Finest Practices for Maintaining Pipeline Stability in Projects

Effective upkeep of pipe honesty is essential for the success of any type of construction task. To accomplish this, normal assessments are vital; these should consist of visual assessments and stress screening to determine any weak points. Correct setup techniques have to be followed to stop future problems. Making use of high quality products that are suited for the certain task atmosphere will certainly also improve durability.

Implementing a maintenance routine can aid in proactively dealing with prospective concerns prior to they escalate. This need to encompass routine cleansing to avoid obstructions and deterioration, alongside checking for leakages. Training workers on the importance of pipe stability and risk-free handling methods ensures that all team members add to preserving the system.

Last but not least, documenting all maintenance activities supplies a clear history that can educate future tasks. By adhering to these best practices, construction teams can secure the longevity and reliability of their piping systems, ultimately adding to project success.

Regularly Asked Inquiries

What Are the Environmental Impacts of Various Pipeline Materials?

Different pipeline materials have varying ecological effects. For example, PVC can launch harmful chemicals throughout production, while steel pipelines may require energy-intensive mining. Eco-friendly choices provide sustainability yet might lack resilience contrasted to standard materials.

Just How Do Climate Condition Impact Pipe Setup?

Weather problems greatly affect pipeline setup, as severe temperatures, rainfall, and wind can affect product integrity, setup strategies, and worker security. Correct planning and changes are important to assure successful installment under varying environmental conditions.

What Certifications Should Pipe Materials Have?

Pipeline products must have qualifications such as ASTM, ISO, and ANSI. These confirm compliance with industry requirements, security guidelines, and top quality guarantee, guaranteeing that the materials used are suitable and trusted for construction projects.

Can Recycled Materials Be Used in Pipe Production?

Yes, recycled materials can be made use of in pipe manufacturing. Several business integrate recycled plastics and metals into their production procedures, advertising sustainability while keeping top quality and efficiency requirements necessary for numerous construction applications.

Exactly How to Make Sure Compliance With Local Building Ordinance for Pipelines?

To ensure compliance with local structure codes for pipelines, one need to investigate particular regulations, seek advice from regional authorities, acquire necessary authorizations, and make use of licensed products while complying with setup practices try this out laid out in the appropriate guidelines and standards.